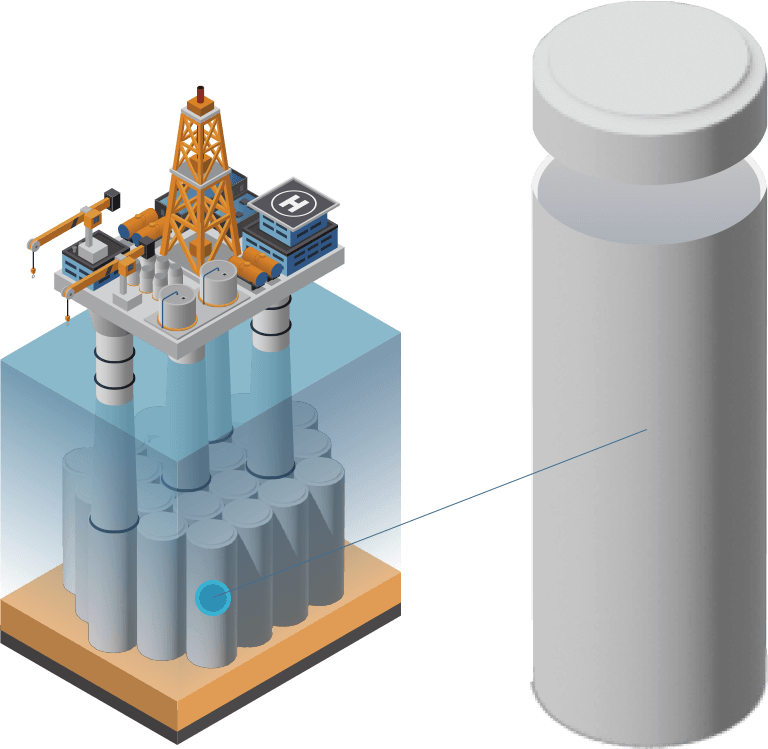

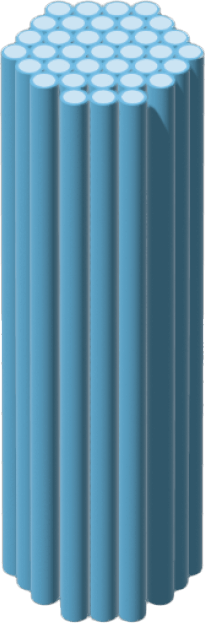

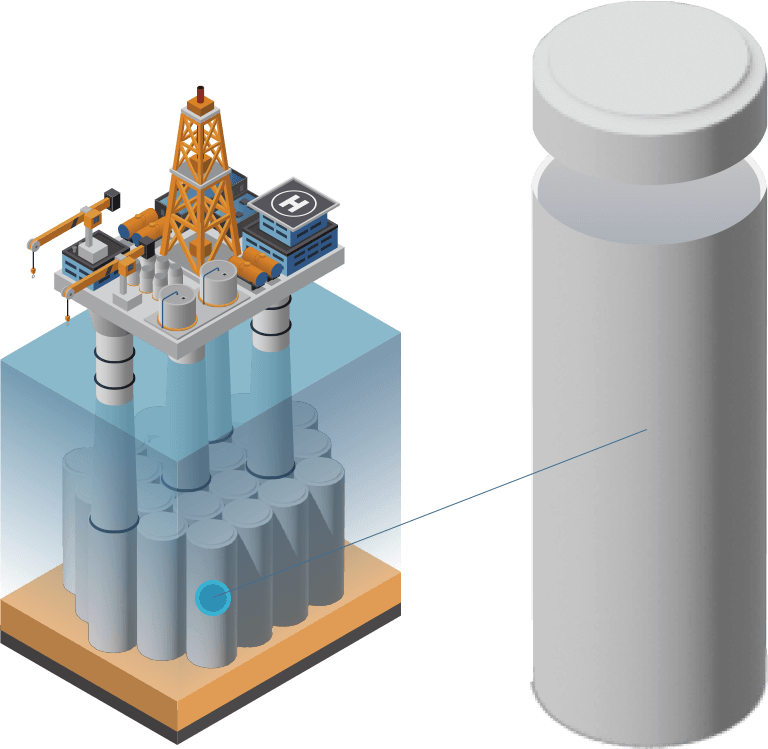

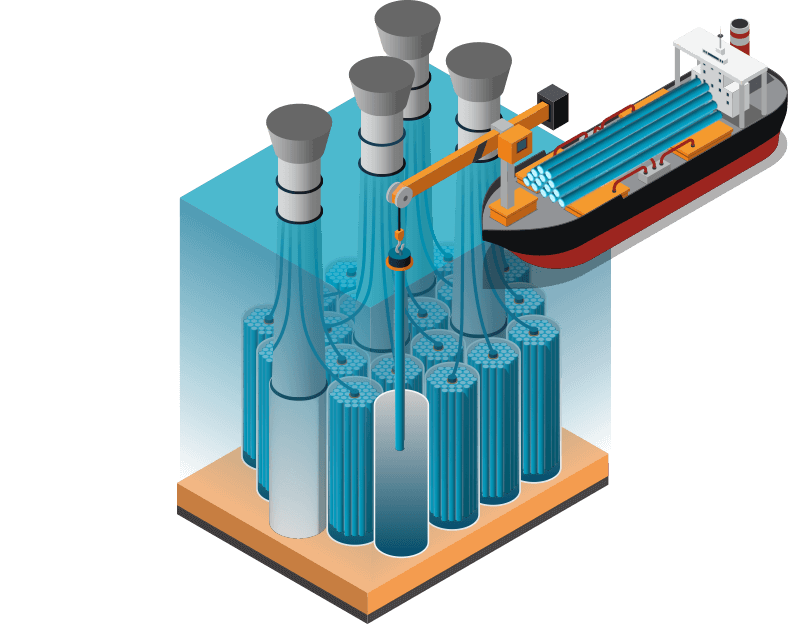

HYDROGEN STORAGE process

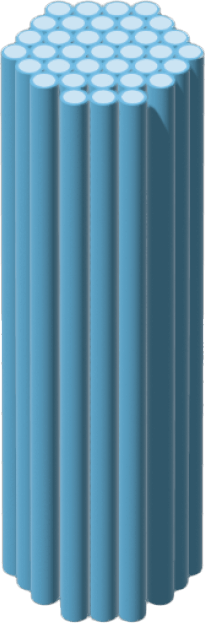

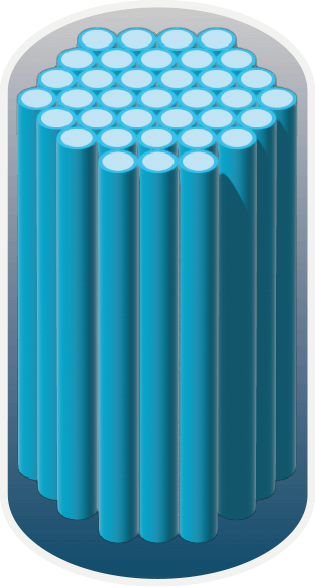

Storage in steel tanks integrated into GBS cells

1 - Cell preparation : « stripping » cell bottom to get full access into the tube

2 - Storage tower construction :

• Pression max : 150 bar

• Internal diameter : 2,5 m

• Length : up to 45 m

• Weight : 250 T

• Carbone steel

• Internal liner H2 hermetic

• Life cycle : 30 years / 1 cycle per day

3 - Tower installation, gas grid connection and pipeline connection

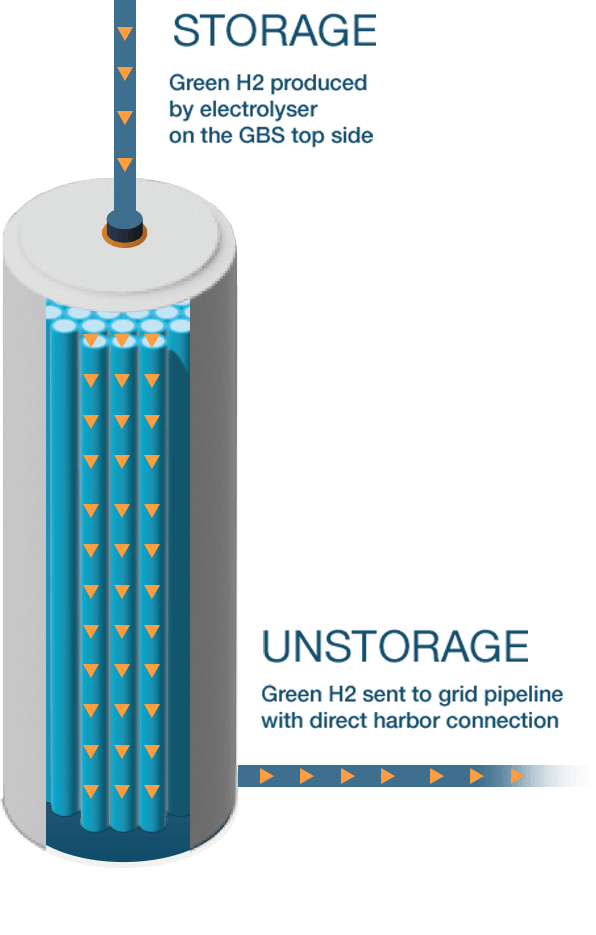

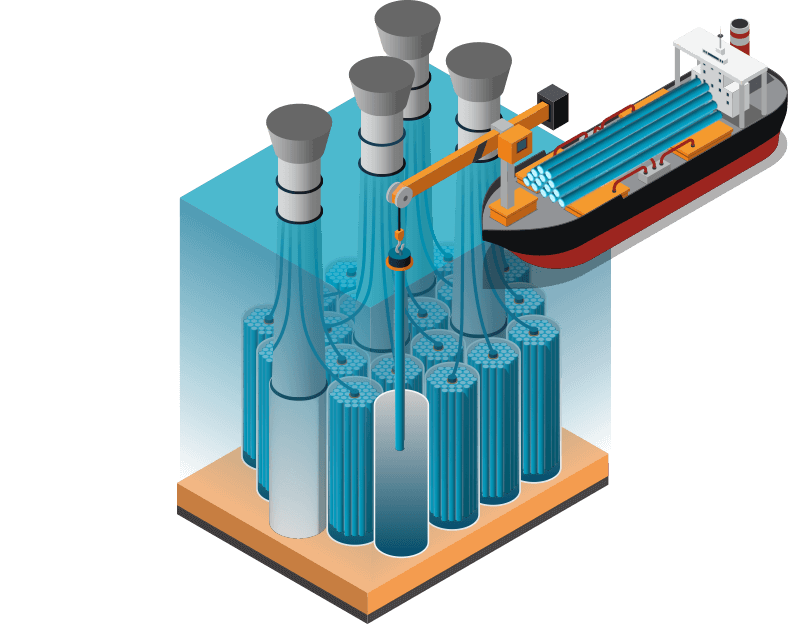

HYDROGEN STORAGE process

Storage in steel tanks integrated into GBS cells

1 - Cell preparation : « stripping » cell bottom to get full access into the tube

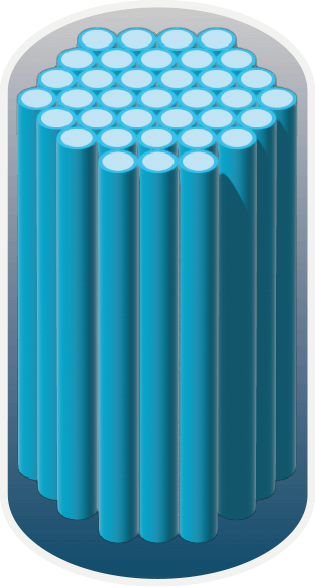

2 - Storage tower construction :

• Pression max : 150 bar

• Internal diameter : 2,5 m

• Length : up to 45 m

• Weight : 250 T

• Carbone steel

• Internal liner H2 hermetic

• Life cycle : 30 years / 1 cycle per day

3 - Tower installation, gas grid connection and pipeline connection

HYDROGEN STORAGE process

Storage in steel tanks integrated into GBS cells

• Relative easy installation

• Existing tools and equipments

• Construction vessels used for wind farm installation

• Standards cranes around 1000 T

HYDROGEN STORAGE process

Storage in steel tanks integrated into GBS cells

• Relative easy installation

• Existing tools and equipments

• Construction vessels used for wind farm installation

• Standards cranes around 1000 T

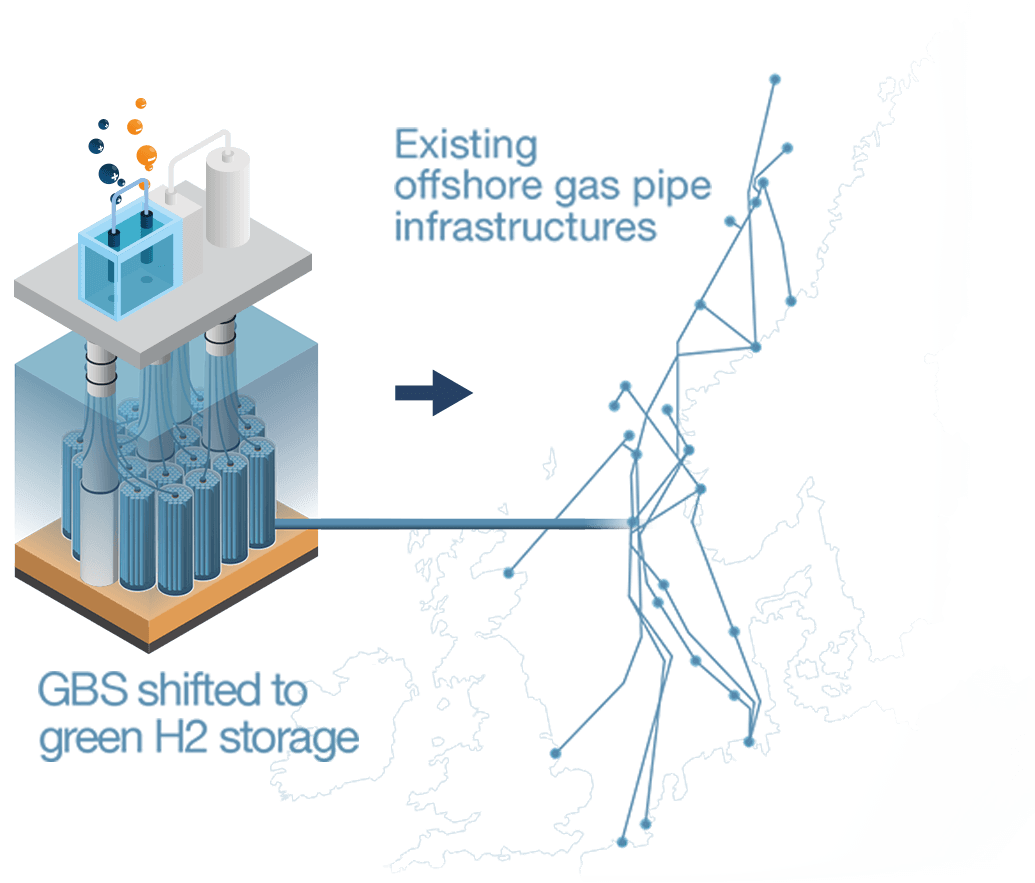

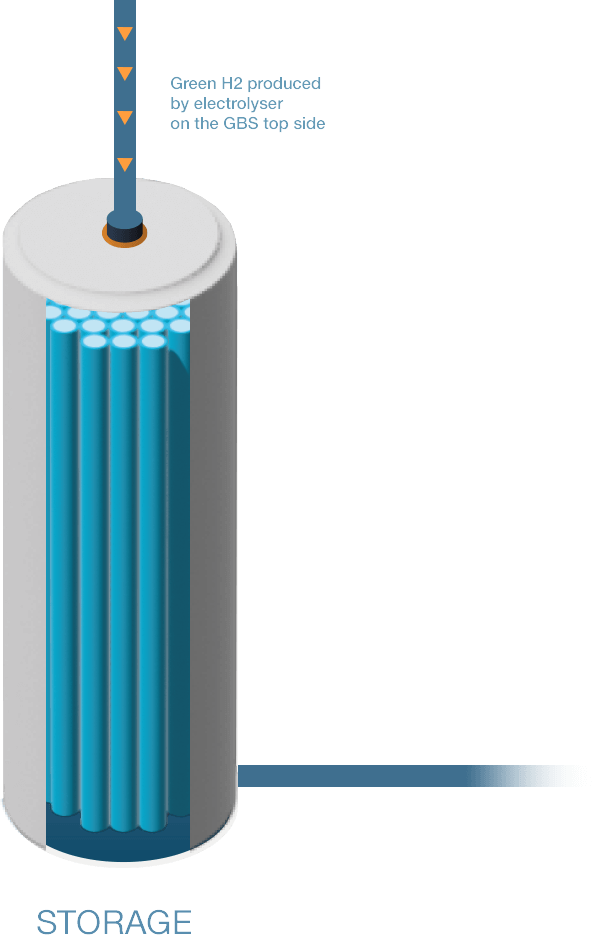

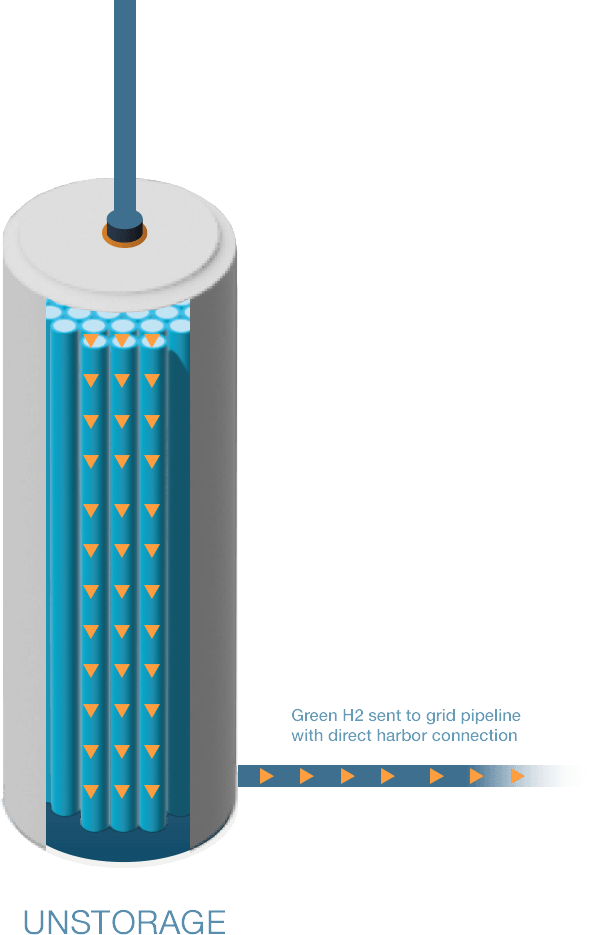

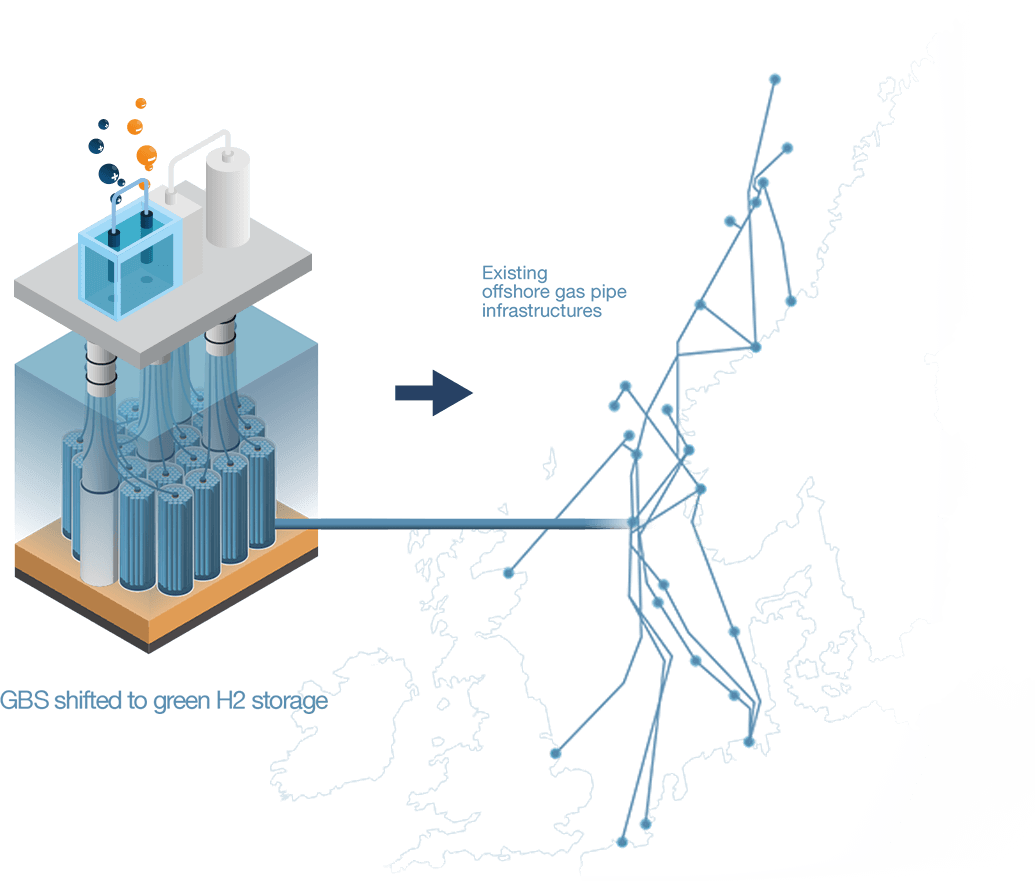

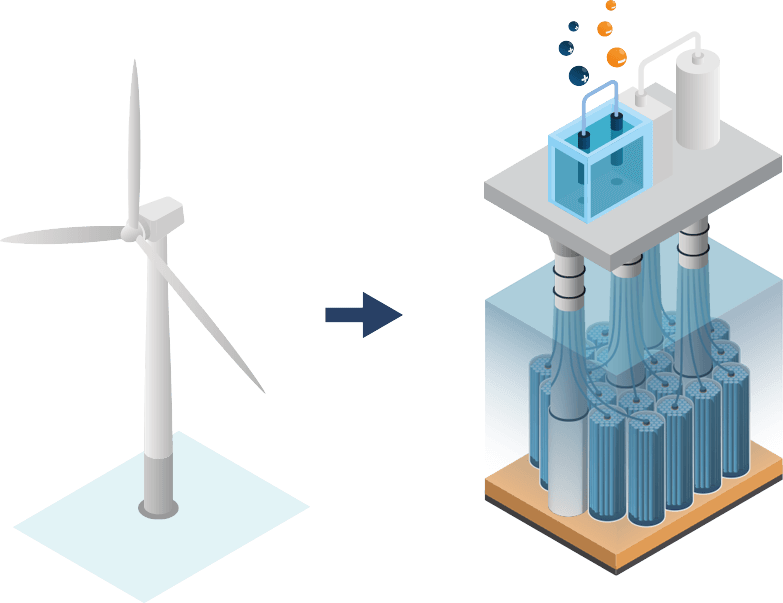

HYDROGEN STORAGE WITH GBS

A unique solution to store hydrogen in existing O&G infrastructure in large quantities.

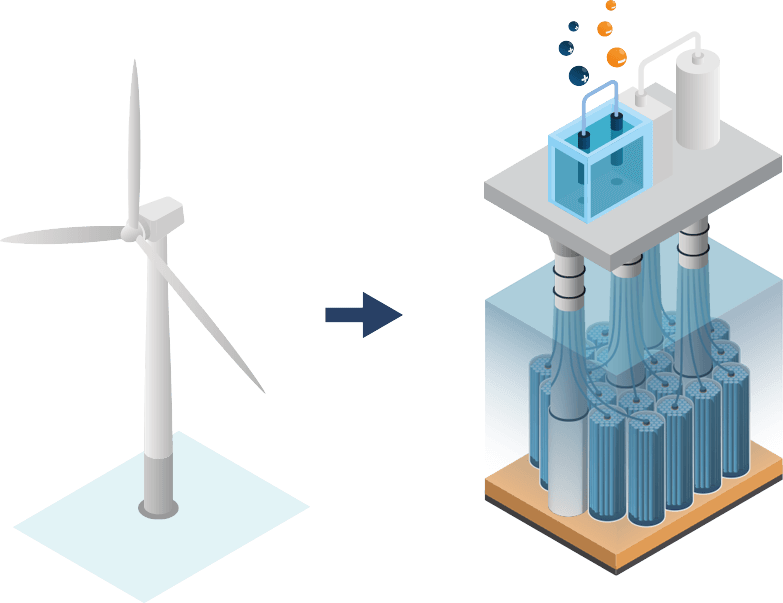

• When the environment is favourable to energy storage (wind production surplus to consumption), GREEN H2 is produced on land or on GBS platforms and then injected into the cell at fixed pressure.

• GREEN H2 is stored for as long as necessary without any loss, the molecule being stored underpressure at a constant temperature equivalent to that of the seabed, about 4°C.

• When GREEN H2 is needed for industrial application onshore, green H2 is sent through gas pipe to the shore.

HYDROGEN STORAGE WITH GBS

A unique solution to store hydrogen in existing O&G infrastructure in large quantities.

• When the environment is favourable to energy storage (wind production surplus to consumption), GREEN H2 is produced on land or on GBS platforms and then injected into the cell at fixed pressure.

• GREEN H2 is stored for as long as necessary without any loss, the molecule being stored underpressure at a constant temperature equivalent to that of the seabed, about 4°C.

• When GREEN H2 is needed for industrial application onshore, green H2 is sent through gas pipe to the shore.